High Level Assembly

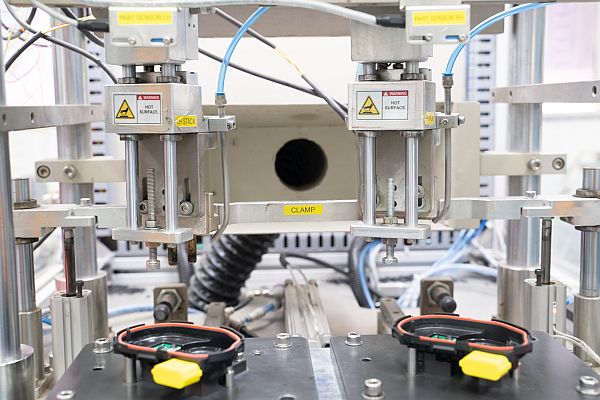

We employ a range of assembly technologies, innovative processes, and quality systems to meet the diverse higher level assembly needs of our customers across multiple industries, including automotive, industrial, medical and RF communications. Our skilled team has deep experience supporting box build, system integration, and testing solutions. Our scalable, system-level manufacturing capabilities provide flexibility in a high mix environment. We manufacture electronic sub-assemblies in self-contained, uniquely configured cells that support specific program and customer requirements.

System assembly and test services include:

- Design for manufacturability analysis

- Prototype to volume production

- Build to order/configure to order

- Real-time ECO/change management

- Board level and system level functional test

- Test design and development

- Order management & logistics

- Distribution & direct fulfillment

- System level testing

- Finished goods stocking

Industry best practices, quality and safety standards, and continuous improvement are critical elements that are built into every aspect of our business. We follow lean manufacturing methodologies to drive efficiencies and effectiveness in higher level assembly production including line balancing and tracking of operation effectiveness, asset utilization, and labor.