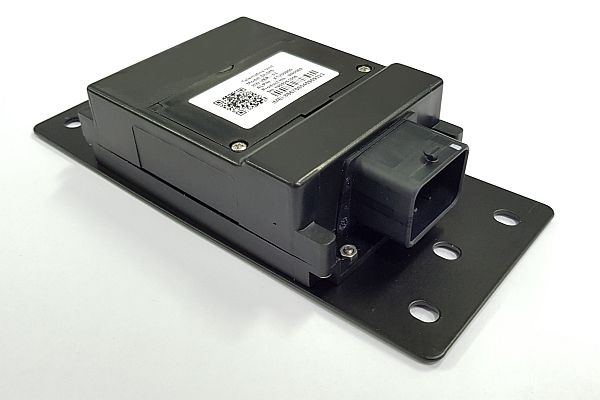

Box Build & System Integration

Box Build Assembly services include:

- Sub Level Product Assembly

- System Level Assembly

- Product Assembly

- Testing including functional, environmental & burn in

- Software loading and product configuration

- Cabling and wire harness assemblies

- Packaging and labeling including barcoding