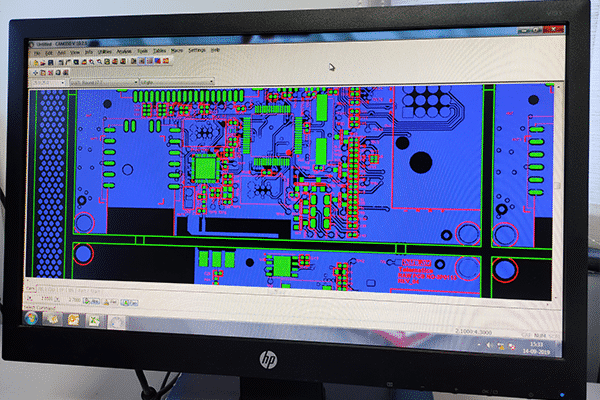

Design For Manufacturability

The purpose is to :

- Ensure the most relia cost-effectivective manufacturing solution.

- Ensure manufacturability fits within our production capabilities.

- Ensure ease of test and function validation.

- Improve product robustness and reliability.

- Improve production cycle times.

DFT – Design for Testability

We can perform a complete review of the circuit design and trace routing to increase the test accessibility. Also increasing the overall coverage for an In-Circuit-Test and to achieve high product yields in volume production stage are our focus areas. Our team can provide a automated test solution for customers as per the test specifications provided. We can leverage from our organisations machine building capabilities and provide complete test solutions.